Warm Pre-Stress

Theoretically, the warm pre-stress operation is recommended to any compression spring, in order to promise smooth and stable operation during the life of the spring.

In most cases the regular/cold pre-stress operation diminishes the potential relaxation to an acceptable extent. The Goodman Diagram might reflect the area where a spring works at a safety region, and the pre-stress operation clearly shows how much the same spring has better quality after it is pre-stressed.

When the spring is supposed to work at extreme condition, either concerning high temperature or at dynamic surroundings, it is recommended to carry out warm pre-stress operation, in order to prevent load loss, due to the relaxation phenomenon.

The warm pre-stress operation is carried out as the final one before packaging, when marking for identification and inspection are not considered.

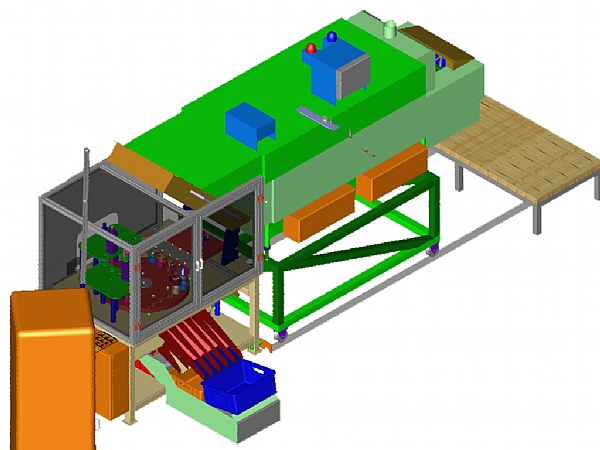

The springs are entered into a conveyor furnace, when they are installed on pins. The velocity of the belt and the temp inside the furnace are determined according to the requirements from the spring, and from its structure. Immediately after the spring finishes the passing inside the furnace it is circulated into a piston which presses it to its solid height, when the spring is still hot. Immediately after the pressing operation, a liquid cools the spring, and the springs are liberated from the piston.

At Nordia Spring’s in-house process, the treated springs are automatically inspected for load and sorted automatically according to requirements.