Technology

Raw Materials

The raw materials we use for our springs are of high level and meet tough requirements, concerning micro-cracks, non-metallic inclusions, de-carburization and narrow tolerances for chemical and mechanical specifications. More

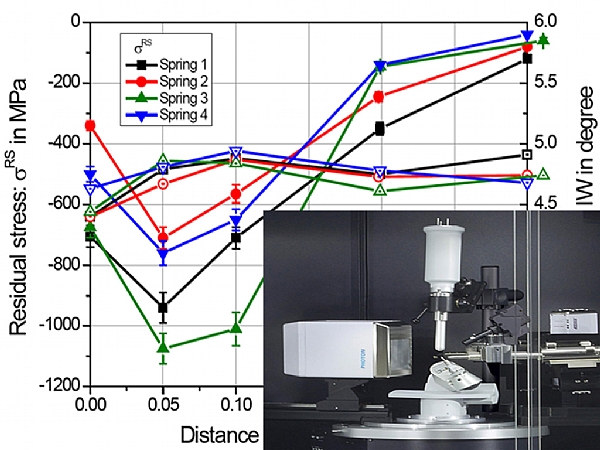

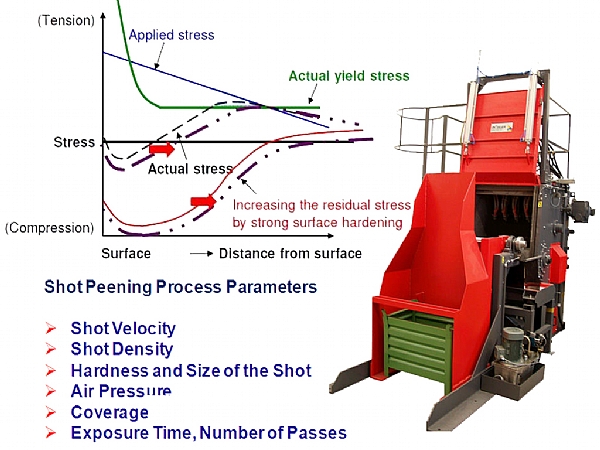

Shot Peening

Shot-peening is a process used mainly to improve the fatigue life of springs. The results are accomplished by shooting small cut-wires made of hardened steel on spring’s surface, at relatively high velocity. The effectiveness of the shot-peening treatment depends to a large extent on the intensity and the coverage. More

Warm Pre-Stress

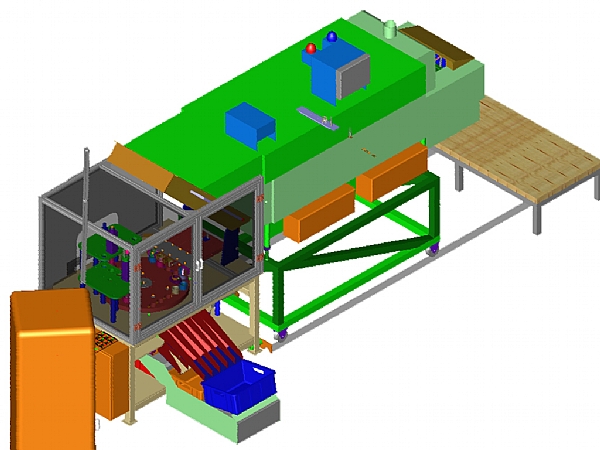

There is a general phenomenon for all compression springs: "relaxation". The spring loses a certain amount of its free length and the exerted load, during its work, particularly, when it works quite close to its elasticity limit, and / or at severe conditions such as high temperature and intensive operation. The relaxation extent is directly influenced by the raw material type and spring structure, especially by D/d ratio. MoreHeat Treatment

Oil quenching and tempering process offer significant advantages to the heavy duty springs because its treatment results can reveal optimum combination of toughness and ductility, and also improves fatigue life. MoreDynamic Tests

In order to investigate dynamical behavior of the springs, they should be tested as close as possible to the real environment i.e. for instance Engine Valve Springs shall be tested in the engines for which they were designed. Besides investigation of dynamic behavior, we are testing durability of springs in order to improve fatigue properties. More